Foam Type: Willtec Melamine

Sheet size: 24″ x 24″

Thickness: 2”, 3” or 4”

NRC Range: 0.85 – 1

SONEX Pyramid panels are typically used for direct-apply, glue-up wall or ceiling panel applications.

$505.75 – $1,004.25

Foam Type: Willtec Melamine

Sheet size: 24″ x 24″

Thickness: 2”, 3” or 4”

NRC Range: 0.85 – 1

SONEX Pyramid panels are typically used for direct-apply, glue-up wall or ceiling panel applications.

Important Pricing Update: Due to recently implemented tariffs, SONEX Online will be adjusting prices by 3% to help offset increased raw material costs. We’ve already taken significant steps to minimize the impact on our customers. If tariffs are reduced or new ones introduced in the future, we will promptly adjust our pricing accordingly.

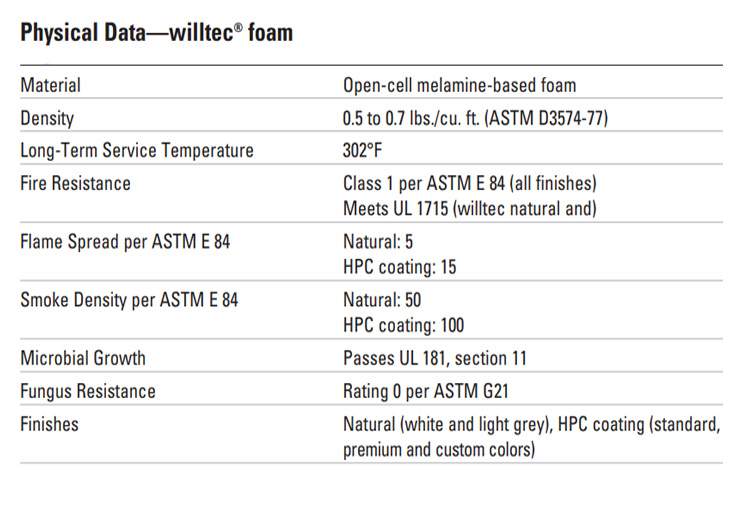

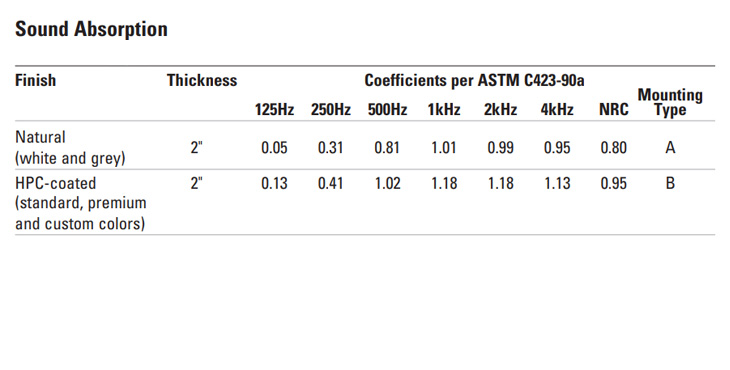

SONEX® Pyramid acoustic foam panels provide optimal acoustic control across all sound frequencies with noise reduction coefficient (NRC) ratings ranging from 0.75 to 1.05. Extended pyramidal shapes significantly increase each panel’s surface area, further enhancing sound absorption. SONEX Pyramid panels are made from SONEX’s WILLTEC® foam, which is Class A fire-rated according to ASTM E84.

| Weight | 9.09 kg |

|---|---|

| Dimensions | 24 × 24 × 31 in |

Size

Applications

Material

Direct-Apply, Glue-up Installation

acouSTIC adhesive (part number PA-02) has been specially formulated to use with all SONEX®, WILLTEC®, CONTOUR®, WHISPERWAVE panel products, PROSPEC® Foams and Composites. This nontoxic, practically odorless, water-based adhesive makes direct-apply, glue-up installation work quick and easy. acouSTIC adhesive provides an immediate tack between panels and most substrates making for strong, permanent bonds. Other adhesives may not be compatible and may emit an odor.

Features

General Installation Notes

Installation with acouSTIC

General tolerances & dimensions stability

Thickness:

– Up to 2” – tolerances of +/- 2 MM = +/- 0.08”

– Above 2” – tolerances of +/- 3 MM = +/-1/8”

Length & width:

– Up to 24” tolerance of +/- 3 MM = 1/8

Sonex convolution:

– Pattern alignment to edge: +/-1”

Due to the nature of willtec material, temperature and humidity may cause dimensional changes of up to 4% by volume.

white

grey

arctic white

medium grey

light grey

black

black*

*Color is impregnated in the foam and has a water-based acoustic coating on top.

Vermillion

Orange Red

Frost

Superior

Olive

Sweet Corn

Brown Black

Dark Grey

brown

charcoal

The Sonex® Acoustic Panel Adhesive has been specially formulated for use with our Sonex® acoustic foam panels.