NRC Range: 0.85 – 1.0

Sheet size: 24″ x 48″

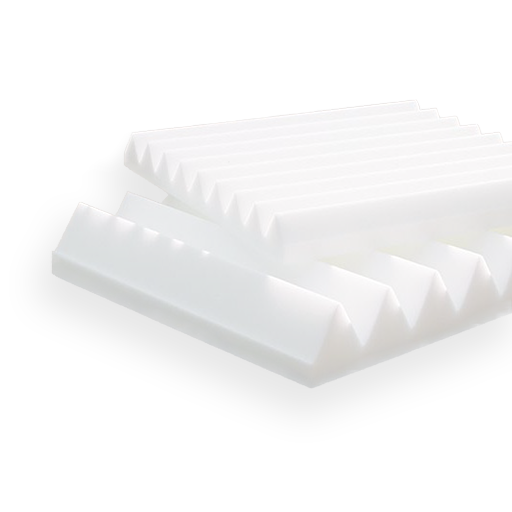

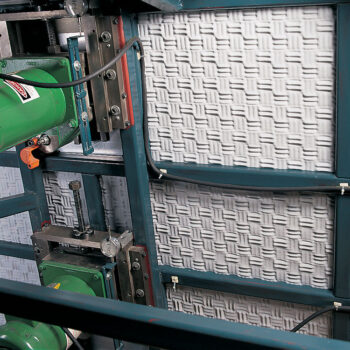

SONEX Tec Wedges give a clean straight look to a space while providing excellent noise absorption.

SONEX Tec Sound Proofing Wedges are used for reducing noise and increasing speech intelligibility. In addition to noise absorption the wedges deflect and scatter sound waves. This wedge shape also increases surface area for better performance. On top of that, SONEX Tec Wedge panels also have high Noise Reduction Coefficients (NRC) of 0.9 for 2″ and 1.0 for 3″.

SONEX Tec Sound Proofing Wedge acoustic foam provides powerful acoustical control with a linear look for use in a range of sound control applications. The anechoic wedge design provides increased surface area for superior sound absorption with an attractive aesthetic.

SONEX Tec Wedge utilizes a Class 1 fire-rated acoustical foam substrate to provide sound absorption. This material is suitable for use in public and private facilities. The Tec Wedge pattern easily installs to create a horizontal or vertical linear design.

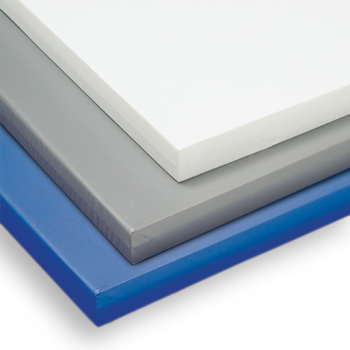

SONEX Tec Wedge acoustic sound proof panels are available in natural grey or natural white colors. HPC coating is available to provide durability and a splash of color. HPC coating is only applied to the panel face. This is acceptable for installations where the panel edges will not be seen. HPC coating can be applied to the edges for an additional fee. These acoustic panels easily mount to any wall or ceiling surface with a water-based construction adhesive.