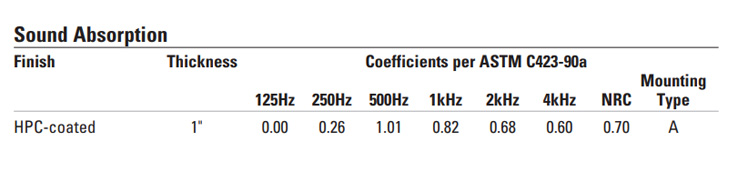

NRC Range: 0.85

Sheet size: 24″ x 48″

Designed for rugged applications requiring a material that absorbs noise and blocks sound from penetrating through it.

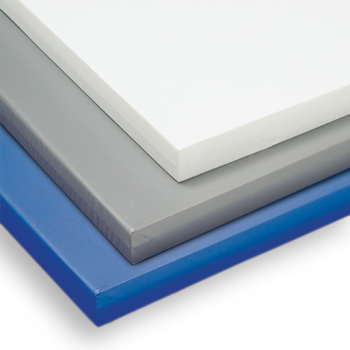

SONEX ProSPEC Foam and SONEX ProSPEC Composite are available with a peel and stick adhesive PSA. We also make a ceiling tile noise barrier which is a thin, uncoated version of our melamine composite for use on top of ceiling tile / drop-in ceilings or for adhering to walls and ceilings.

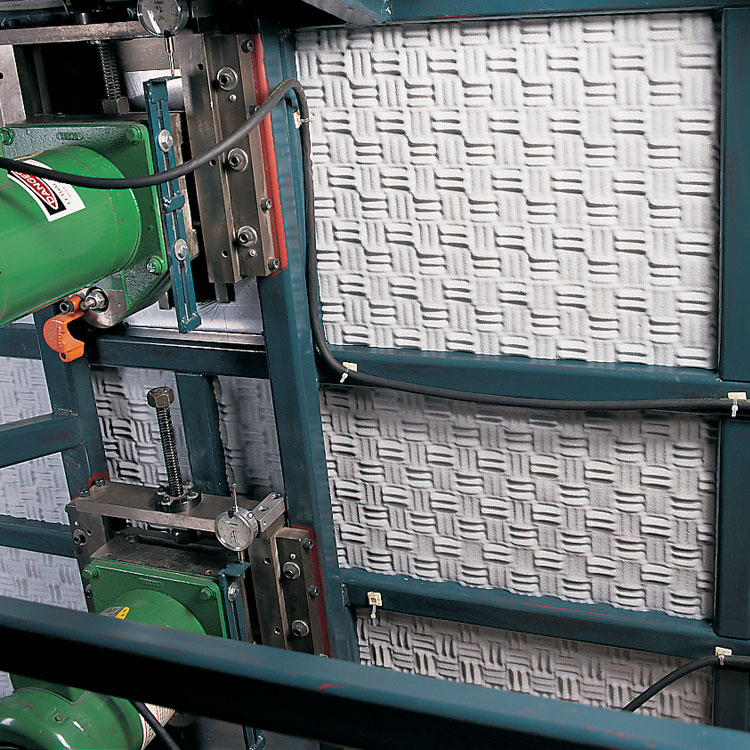

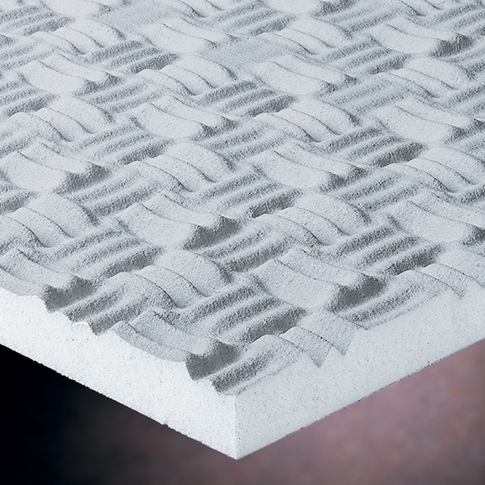

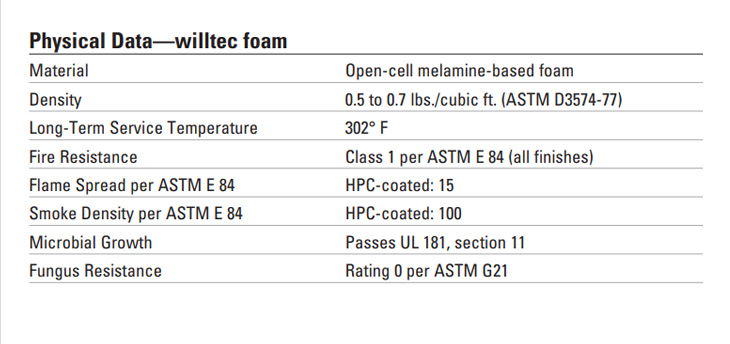

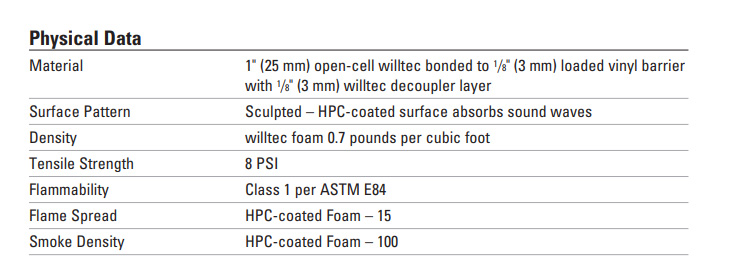

SONEX ProSPEC foam is made of a 1” fire resistant melamine foam with a light gray cleanable HPC coating.

ProSPEC Composite is the same as SONEX ProSPEC but adds adds a 1 lb./sq.ft. noise barrier that prevents noise from going through the material, stopping the sound in addition to absorbing the sound.